Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

At present, various types of torque wrenches have been widely used in many industries, and the torque wrench calibrator is also widely used as a measuring instrument for torque wrenches.

However, at present, the torque wrench calibrator still uses the method of hanging with weights and levers for verification and calibration, which makes the verification and calibration of the calibrator inconvenient.

In 2013, the National Metrology Department revised the "JJG797-1992 Torque Wrench Verification Regulations". The standard torque wrench is a high-accuracy torque wrench used to transmit the value of the torque wrench calibrator. It is specified as torque wrench verification. Instrument verification equipment, currently used verification procedures are: JJG1103-2014 standard torque wrench verification procedures.

1. Appearance structure and its composition

The outline structure of the standard torque wrench is shown in Figure 1 below. It consists of four parts: a torque digital display instrument, a high-precision sensor, a wrench head and a wrench rod. The high-precision sensor is installed and fixed on the wrench head and is integrated with the wrench head. High-precision sensor and torque digital display form the torque acquisition and processing part.

2. Product Features

1. Adopt microprocessor digital technology;

2. Delayed automatic shutdown and manual shutdown;

3. Anti-corrosion keys, impact resistance, good long-term stability;

4. Arbitrary alarm value setting, sound and light alarm.

5. Start zero tracking;

6. The value of the three units is automatically converted.

3. Technical parameters

* Measuring range: 20% to 100% of full scale

* Accuracy class: 0.3 class/0.1 class

* Working temperature: 20℃±5℃

* Relative humidity: ≤80%

* Power supply: 220VAC 50Hz

* Peak hold/real-time tracking

* Left and right rotation two-way detection

* Peak alarm

* 6-digit digital tube display

* Four units of N.m, Ibf.ft, kgf.cm, mV/V

4. Precautions

This product is a high-precision product. For this reason, the manufacturer reminds you to pay attention to:

1. Do not give strong impact during use, so as not to damage the sensor and electronic components. It is strictly forbidden to store it with corrosive, flammable and explosive materials;

2. It cannot be used as a hammer to strike the workpiece;

3. When tightening the thread, the force-applying part should be near the force-engraving line of the handle. When the torque value is close to the predetermined value, the force should be applied as smoothly as possible to make the measurement more accurate;

4. Do not continue to apply force after the digital torque wrench alarms to prevent overload damage to the tightened workpiece.

5. When the voltage of the working battery drops to the specified voltage value and the under-voltage indicator " " is displayed on the liquid crystal display, it means that the battery is insufficient and should be charged in time. The first charge is at least 10 hours.

6. During use, if you find any quality problems, please contact the manufacturer or seller.

7. The product has been calibrated at the factory, and must be operated by professionals during the verification.

Commonly used models are recommended: MDJJB-1000 (100-1000N.m) \ MDJJB-100 (10-100N.m) of class 0.3, etc.

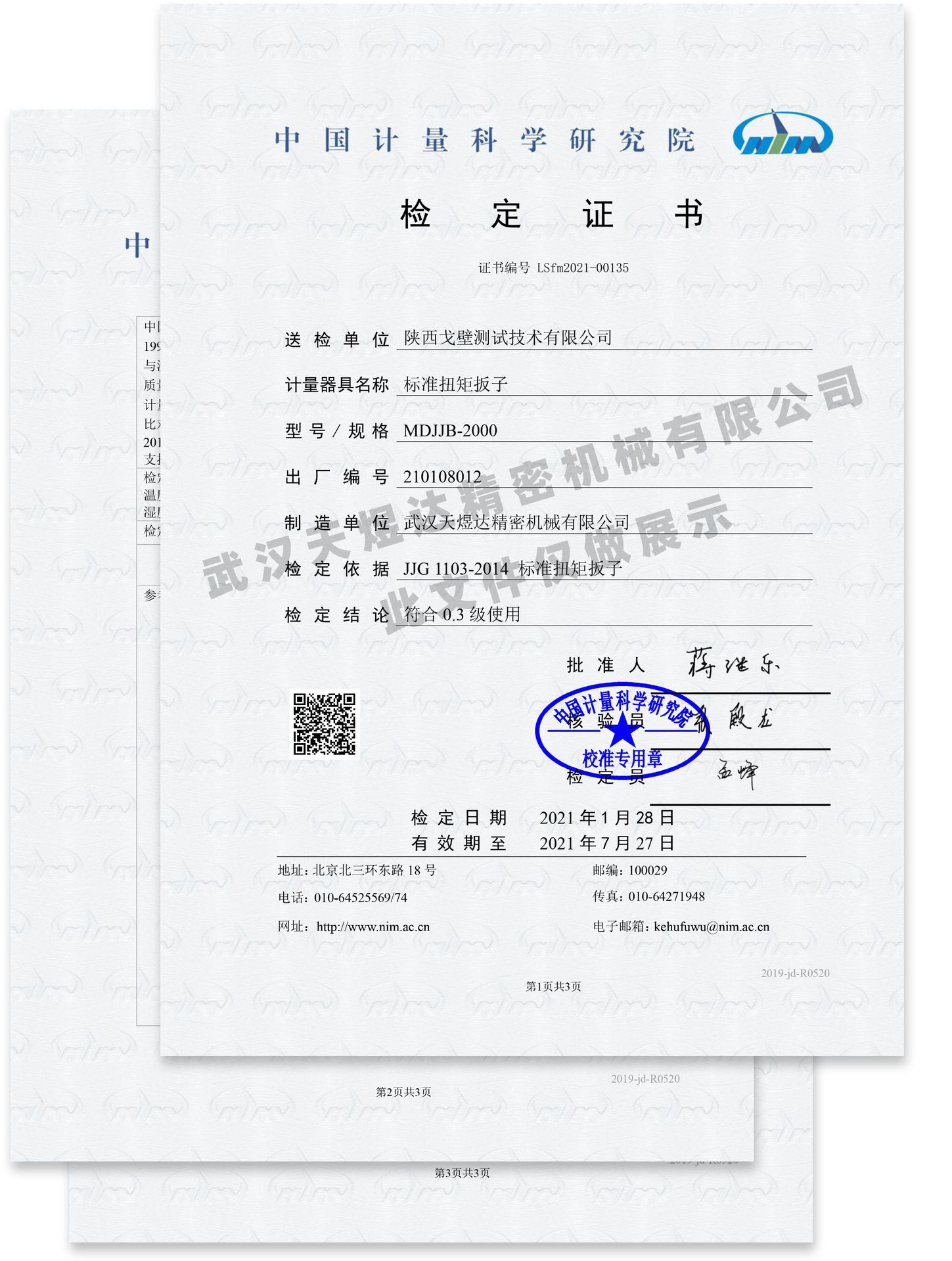

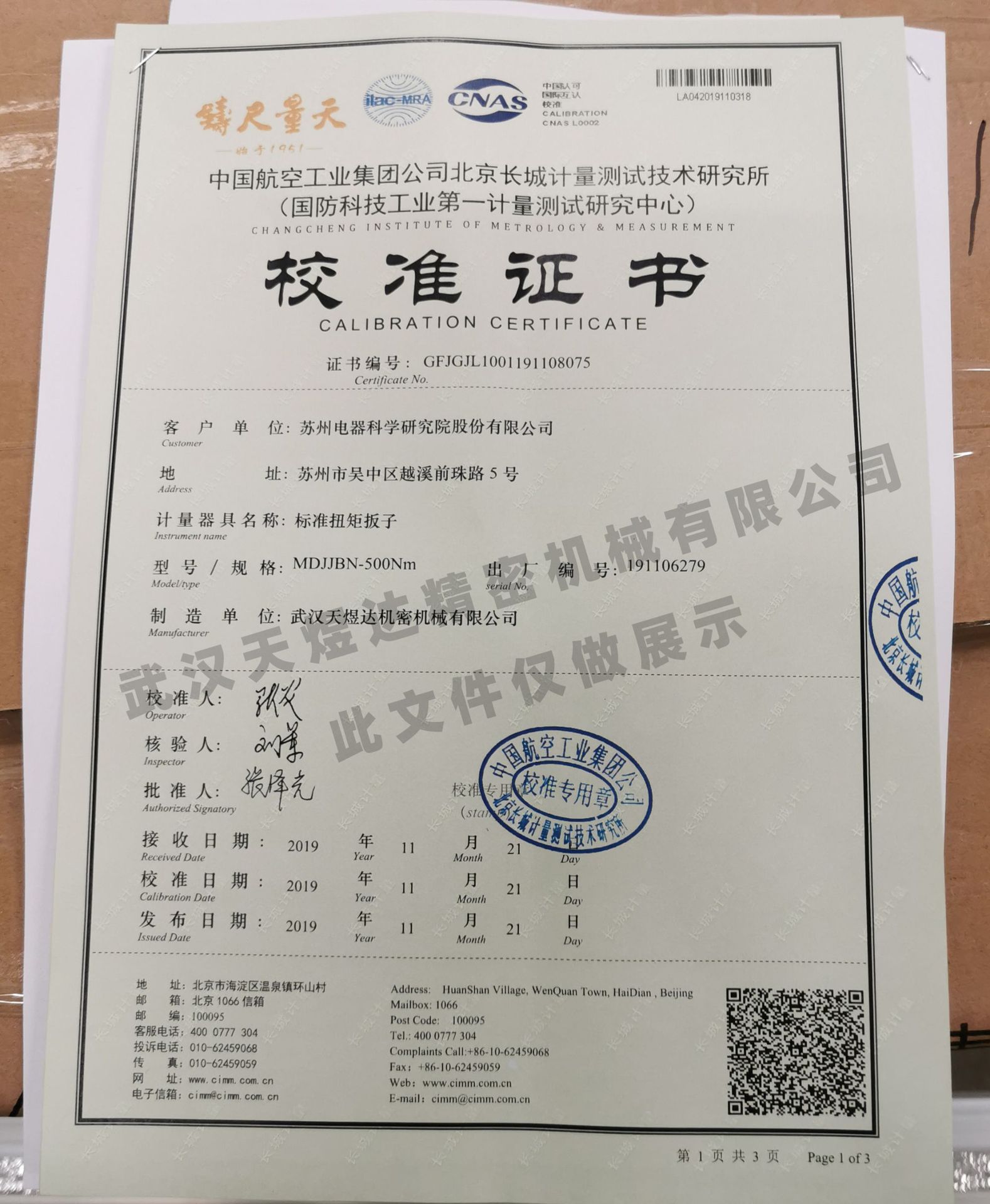

Third-party measurement and test reports are available, as follows