Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Product Introduction

LN series torque wrench calibrator is a high-end torque testing equipment that can detect a variety of static torque tools. Incorporating a number of performance-enhancing R&D achievements and human-friendly design concepts, it is easy to use, easy to operate, and safe to protect, making the detection work handy. Optimized structural design, precise control loading system, excellent stability, repeatability, anti-interference, can meet the requirements of the detection process, improve work efficiency, reduce the operator's work intensity, suitable for large and medium-sized enterprises, Metrology institutes (institutes), high-speed railways, etc. have demand for the replacement of torque detection equipment.

Technical Parameter

Product Features

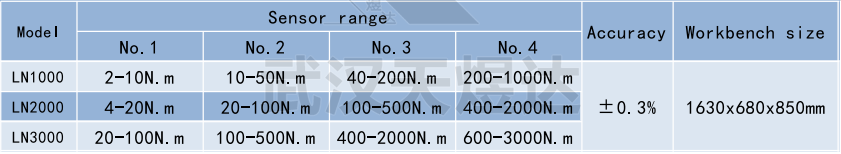

1. Measuring range: forward and reverse 2-1000Nm (configured with 4 sensors of 10N.m, 50N.m, 200N.m, 1000 Nm, and sensors can also be configured according to customer requirements);

2. The basic display error of the whole machine: ±1% (accuracy of the whole machine ±0.3% can be provided);

3. It adopts full-color dot-matrix high-precision liquid crystal display instrument, the display screen is processed in Chinese, and the operation is completed through the touch screen, with a computer data processing system;

4. The display instrument can match 4 sensors. The display instrument has 3 international torque measurement units that can be freely switched;

5. Computer data collection, processing, storage, query, printing and other functions;

6. The use of servo motor and precise star-shaped deceleration mechanism to drive the sensor to rotate the booster device is more labor-saving, less system error, stable operation, and more accurate detection data;

7. Loading or unloading through the electronic handwheel, the speed of loading or unloading can be adjusted, and there is an overload alarm reminder function;

8. The sensor can be replaced quickly without tools;

9. The variety of adapters is complete and can be replaced quickly;

10. The design standard is in accordance with the requirements of "JJG797-2013 Verification Regulations for Torque Plate Verification Instrument";

11. Table size: length 1630mm, width 680mm, height 850mm;

12. Display mode: peak hold and continuous display;

13. Power supply: AC220V±10%, 50HZ.

Product parts introduction

1. Display instrument 2. Sensor 3. Afterburner 4. Slider 5. Control cabinet 6. Power switch 7. Electronic handwheel

Note:

1. The load exceeding 120% of the maximum range of the range cannot be detected!

2. Be sure to change the meter range setting after replacing the sensor, and make sure it is correct before loading!

3. When replacing the sensor, be sure to pay attention to the position of the output plug of the sensor and the signal line to ensure that other parts are not touched during the entire loading process, and the signal line is in a free state.

Special reminder: The sensor can only be rotated at a certain angle. When installing, the sensor output connector should be placed in a suitable position. When the electronic handwheel is loaded and unloaded, prevent the sensor from turning too large to avoid damage to the sensor! ! !

Technical specifications of LN 2000

1. Measuring range:

Range A: 400N.m ~ 2000N.m

Range B: 100N.m ~ 500N.m

Range C: 20N.m ~ 100N.m

Range D: 4N.m ~ 20N.m

2. Measurement accuracy: ±1% (accuracy of the whole machine ±0.3% can be provided)

3. Alarm value setting range: within the full scale range

4. Conditions of use

(a) Ambient temperature: 0~40℃

(b) Relative humidity: ≦80%RH

(c) Power supply: AC 220V ±10% 50Hz