Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Product Description

MDJ series dual-range torque wrench tester is a test instrument used for calibrating various torque wrenches. The instrument adopts single-chip control technology and is composed of high-precision torque sensor and force support. Its test is accurate, the performance is stable, the function is rich, and the operation is simple. The instrument adheres to the leading technology of Confucianism in the industry, and its various indicators have reached the domestic first-class level. It is a test instrument with high cost performance. Automobile, ship, aircraft and other manufacturing industries and measurement and testing departments.

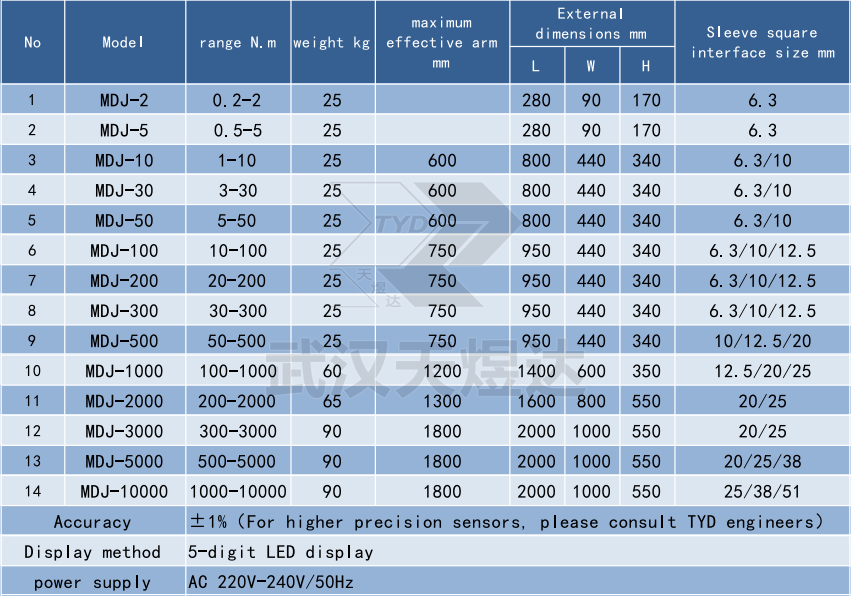

Technical Parameter

Product Features

1. Adopt microprocessor digital technology;

2. High brightness LED display;

3. Humanized design, the display viewing angle is adjustable;

4. Clockwise/counterclockwise torque direction display;

5. Alarm value setting function;

6. Automatic conversion of three measurement units (lbf.in kgf.cm N.m);

7. With RS232 interface, it can be used for data recording and printing (not standard in factory);

8. The maximum torque can be maintained, so the precise torque can be set for the tool;

9. The structure part is simple and firm, and the design principle is scientific;

10. Stable performance and easy operation.

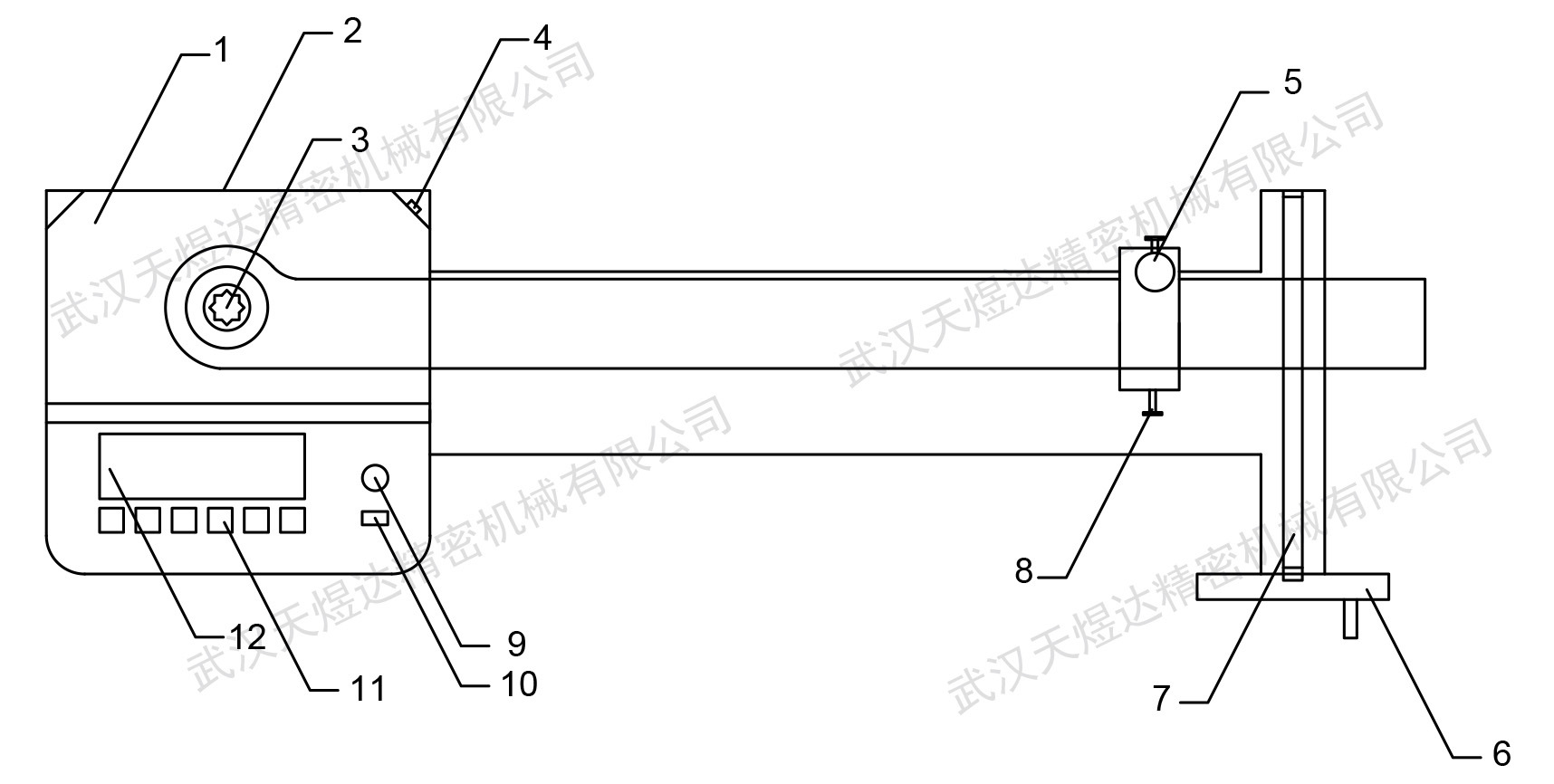

Product parts introduction

-1. Chassis;

-2. Power socket (AC220V);

-3. Sensor force head: several conversion test heads are equipped according to the size of the square head of the torque wrench before leaving the factory;

-4. Aviation connector: The instrument can be calibrated through this connector;

-5. Height adjustment button: The height of the platform can be adjusted so that the torque wrench to be measured is in a horizontal state. If it is not in a horizontal state, it may cause measurement errors;

-6. Drive handwheel: load or unload the torque wrench under test;

-7. Screw;

-8. Left and right adjustment buttons: adjust the test platform to suit the arm length of the torque wrench under test, and also adjust the direction of the test platform to suit the forward and reverse measurement of the torque wrench;

-9. Switch range button: When switching between different ranges, you need to turn this button to switch;

-10. Power switch: (POWER);

-11. Function keys: each key required for setting and operation;

-12. Display screen: display data such as torque value;