Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Product Description

MDB series dial torque wrench is a high quality torque wrench produced by our company. It uses the pointer to intuitively indicate the torque value of the tested nuts, bolts and other fasteners on the dial, and memorize the torque value. It is composed of wrench body, elastic element amplification mechanism and memory mechanism, etc. It has the characteristics of high precision, beautiful appearance, convenient use, good reliability and replaceable head. Widely used in aerospace, aviation, ships, automobiles, railways, construction machinery, electric power and other industries, the MDB dial torque wrench can measure torque on the left and right sides, with an accuracy of ±3%.

◆Main components: wrench body, elastic element, magnifying mechanism, display mechanism and memory mechanism are composed of five parts;

◆Performance characteristics: torque can be measured from left and right, beautiful appearance, easy to use, high precision and long service life;

◆Applicable industries: aerospace, aviation, ships, automobiles, precision machinery, electric power, generators and other industries that have strict requirements on the tightening torque of threaded parts.

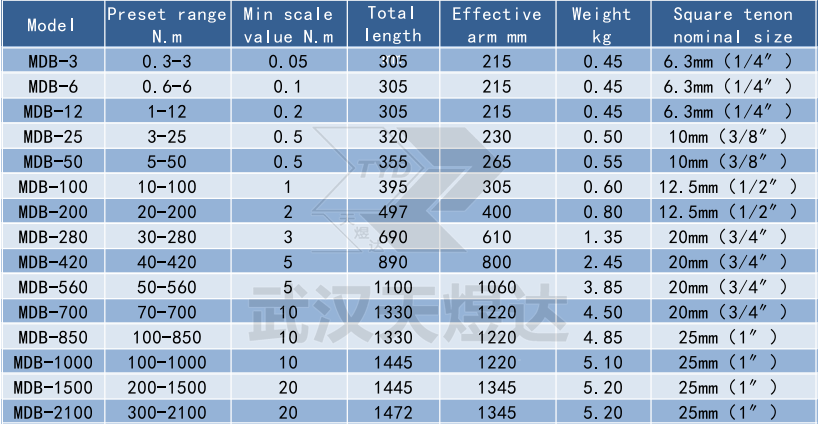

Technical Parameter

How to use the dial wrench?

MDB type torque wrench is an instrument indicator used for torque measurement of threaded fasteners, which can be tested arbitrarily within the range. Suitable for torque testing of fasteners requiring high accuracy.

1. Before use, the zero position must be adjusted first!

(1) When using with clockwise rotation, turn the knob on the top of the dial counterclockwise to make the red driven pointer close to the black active pointer; rotate the case to make the driven pointer go to the zero position of the dial torque line.

(2) When using left-handed rotation, turn the knob above the dial clockwise to make the red driven pointer close to the black active pointer; rotate the case so that the driven pointer points to the zero position of the dial torque line.

2. When using, the tightening force should be applied slowly and steadily until the driven pointer reaches the required torque value.

3. After the application of force is stopped, the active pointer automatically returns to zero position, and the driven pointer still stays on the indicated scale value, and the torque value can be read out accurately. Rotate the knob above the dial to make the driven pointer return to zero for the next use.