Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Product Description

MDS Series digital torque wrench adopts a high-precision, low-power intelligent microprocessor as the core control chip, and applies digital processing technology and strain sensing technology to accurately and intuitively display the measured tightening torque with a four-and-a-half-digit liquid crystal display. its torque. The product has accurate display, stable performance, long life, low power consumption, and easy to use. It is equipped with a variety of torque preload and measurement modes, and can store 100 sets of detected torque value data in peak mode, which can be used to store data. Communication with the computer enables operators and testing personnel to conveniently view, process, analyze, backup, and print the recorded data, and effectively control and ensure the quality of the fastener pre-tightening and measurement process. Widely used in aviation, aerospace, automobile, motorcycle, precision machine assembly occasions to ensure accurate preloading and measurement of fasteners.

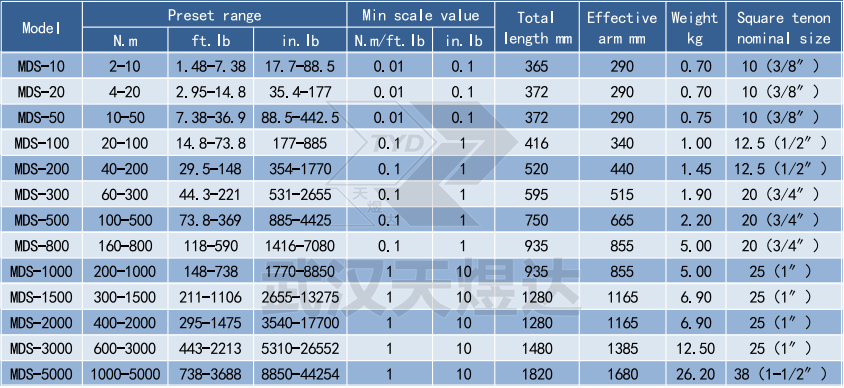

Technical Parameter

Product Features

●Indication tracking: During the process of adding force, the added torque value is tracked and displayed, and the LCD display shows 0.0 after unloading.

Peak hold: During the application of the force, the displayed value increases with the tightening torque. When the force is stopped, the displayed value is the maximum torque value before the force is stopped. The user can check the magnitude of the torque value, and can Store this torque value.

●Preset alarm: preset the required tightening torque before tightening. During the tightening process, when the tightening torque reaches the preset torque value, the preset alarm light will light up and the alarm sound will sound, prompting to stop the afterburner .

●The value of five torque units can be automatically converted (N.m, in.lb, ft.lb, kgf.cm, kgf.m) to adapt to the application of different torque units.

●Wireless data transmission.

●Station screw programming.

●Undervoltage display: When the working voltage drops to 2.9V, the undervoltage display symbol "" in the liquid crystal display flashes, and the user is prompted to replace the battery.

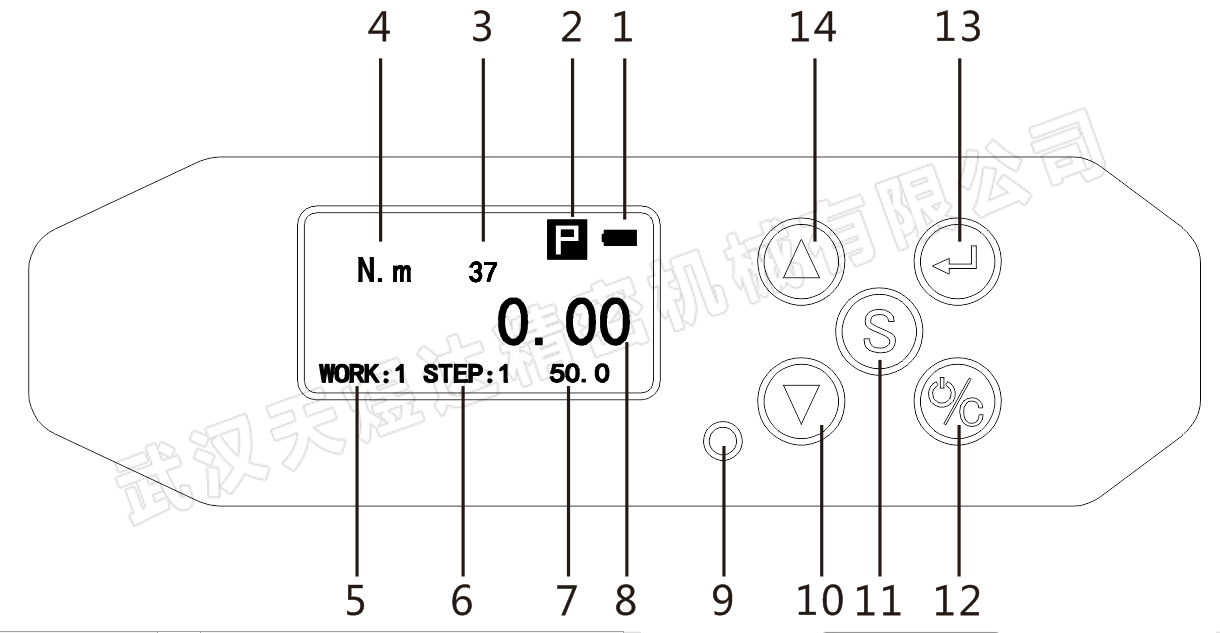

Operation panel and key description

1. Battery power indication 2. Mode indication 3. Number of stored data 4. Torque unit

5. Work station 6. Operation steps 7. Preset torque value 8. Current preset value

9. LED indicator 10. Down button (-)▼ 11. Setting button 12. Power on and off, clear button

13. Enter to confirm key 14. Up key (+)▲

MDS series advantages

1. OLED high-definition LCD display

2. The five torque units can be switched arbitrarily

3. Positive and negative bidirectional accuracy ±1%,

4. Large capacity rechargeable battery

5. Remo communication interface,

6. A maximum of 4000 sets of data can be stored

7. Blue, green and red three-level sound and light alarm function

8. Contains aluminum alloy packing box, beautifully packaged to better protect the product