Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Product Description

The preset torque wrench is a high-quality torque wrench developed and produced by our company. The product series is complete and has the characteristics of high precision, beautiful appearance, convenient use, good reliability, and replaceable head. It is widely used in aerospace, aviation, ships, automobiles, railways, construction machinery, electric power and other industries. It is an essential tool to ensure and improve product quality. The accuracy is ±4%, and our company can also adjust it to ±3% according to requirements. MD-680 (including MD-680 and above adopts split design, paying more attention to the needs of customers in packaging, transportation and storage.)

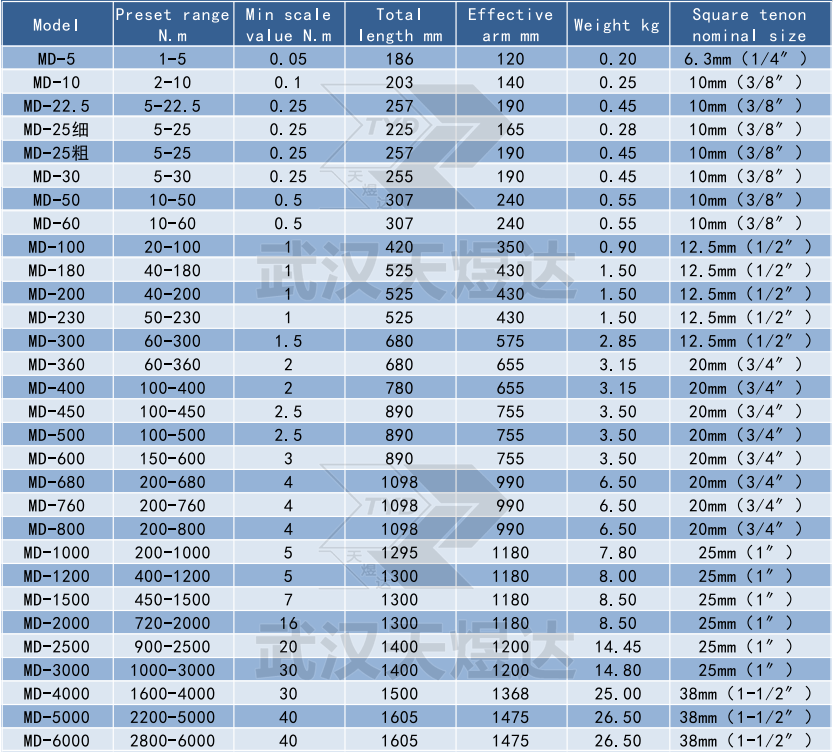

Technical Parameter

Product Features

◆With preset torque value and sound device. When the tightening torque of the fastener reaches the preset value, a signal "click" (click) can be automatically issued, accompanied by obvious hand vibration, prompting the completion of the work. After the force is released, the relevant parts of the wrench can be reset automatically.

◆Can switch between two directions. Toggle the head reversing plate, and the wrench can be counter-clockwise to add force.

◆Handle differential tick marks. The readings are clear and accurate.

◆Forged alloy steel material, durable and long life.

How to use the preset wrench?

1. Determine the preset torque value according to the torque value required by the workpiece.

2. When the torque value is preset, loosen the lock nut at the end of the wrench, and turn the adjustment wheel at the same time to adjust the value of the main scale line and the differential scale line of the ruler to the required torque value. After adjustment, tighten the lock nut.

3. Install the corresponding specification sleeve on the square tenon of the wrench, and cover the fastener, and then slowly apply force on the handle. When applying external force, it must be in the direction of the marked arrow. When tightening to a "click" signal (the preset torque value has been reached), stop applying force. One job is done.

4. When using a large-sized torque wrench, a long sleeve rod can be added for easy operation.

5. If it is not used for a long time, adjust the scale line to return to the minimum torque value.