Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

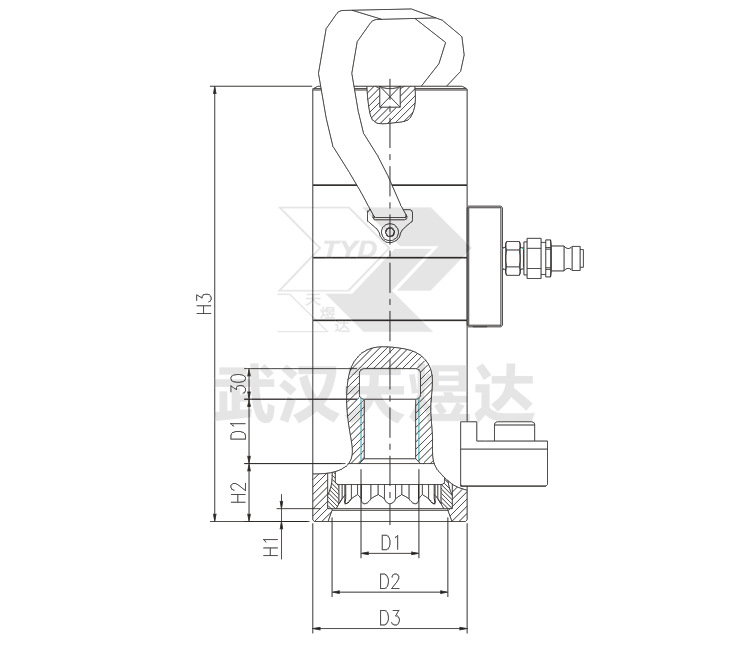

MSD series multi-stage hydraulic bolt tensioner is a high-quality hydraulic bolt pre-tightening and dismantling tool, which precisely controls and guarantees the pre-tightening force of the bolt connection. It is an ideal tool to improve the quality of bolt connection and improve labor efficiency; multi-stage hydraulic tension The diameter of the device is small and the tensile force is large, which is suitable for the pre-tightening of bolts in small spaces, especially the pre-tightening of imported bolts (grade 10.9 bolts). Widely used in metallurgy, machinery, chemical industry, power station, shipbuilding, cement, coal, pressure vessel and other machinery and equipment assembly, installation and maintenance.

Features:

Choice of working conditions:

Test report case

maintenance

MSD series multi-stage hydraulic bolt tensioner is made of high-quality alloy steel, the maximum working pressure is 150MPa, the pre-tightening force is displayed by the pressure gauge of the special hydraulic pump station, which can be used to tighten or remove the nut, and the high-pressure hose is connected by a quick joint, It is easy to operate and use; the same two-stage hydraulic tensioner can be equipped with different specifications of tie rods to be suitable for different specifications of bolts, reducing the number of tensioners as much as possible, thereby reducing economic costs.

- Mainly used for 10.9 grade bolts - Maximum working pressure 15OMPa

- Automatic quick return mechanism - Red travel indication line, over travel indication

- Replaceable stretch head - Polished finish (blackened)

- Overtravel Limiting Mechanism - Multi-stage, as the name implies, contains multiple cylinders

Optional:

- Safety cover - Swivel nut sleeve with spring

- Optional nickel plated finish - Optional distributor fitting

- Optional bolt elongation measuring rod

1. All parts of the stretcher should always be kept clean, and there should be no dust and dirt around the oil pump, oil cylinder and hose.

2. The working fluid is L-HM32 or L-HM46 hydraulic oil. It is strictly forbidden to use alcohol, water, glycerin, brake oil, ordinary engine oil, etc. as the working fluid.

3. The working fluid should be replaced once a year, and it must be filtered and cleaned with a 120-200 mesh filter.

4. When not in use, avoid damage to the lever and gear, and should be stored in a dry, suitable temperature room.

5. The high-pressure oil pipe should be kept properly, and should not be corroded by corrosive gas and liquid. Due to long-term use and storage, hoses are prone to aging, and should be checked regularly and replaced regularly. The hose shall be subjected to a pressure test once a year.

6. When replacing the cylinder seal, the seal must be installed in the seal groove, otherwise the pressure cannot be built up.