Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

◆ Using compressed air as a power source, it is generally used in coal mines and other occasions, explosion-proof, safe, and non heating.

◆ Use high-performance pneumatic directional valves for safety, reliability, and stable performance.

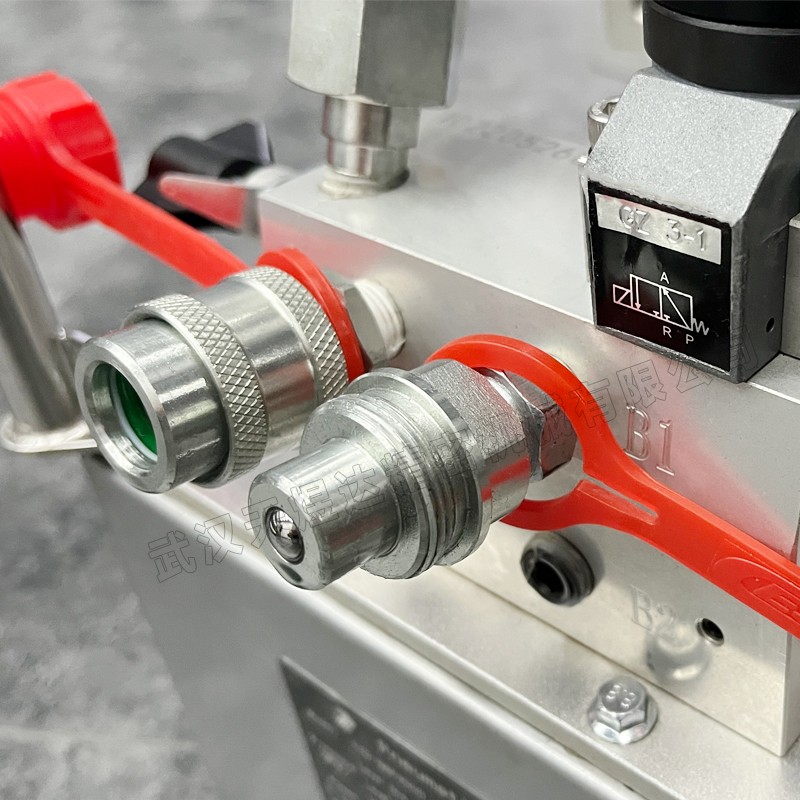

◆ 4-70MP output pressure can be freely adjusted.

◆ Manually switch the cooling device, which can work for a long time.

◆ External pressure regulator with built-in release valve protection tool.

◆ The pump station is made of aluminum titanium alloy, which is lightweight and easy to carry.

◆ Can simultaneously drive 2 hydraulic torque wrenches (or 4 as needed).

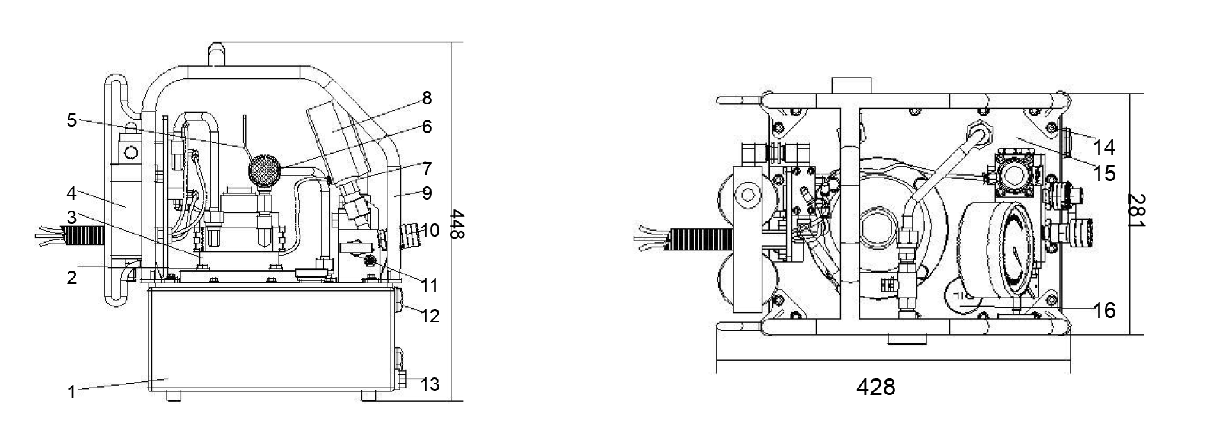

1. Oil storage tank: stores hydraulic oil for work, ensuring the normal operation of the system (there must be sufficient oil volume), and provides the pressure carrier required by the system.

2. Pressure regulating valve (overflow valve): Adjusting this valve can set the working pressure of the hydraulic pump (the highest working pressure is locked at the factory, and it is prohibited to increase the locking pressure).

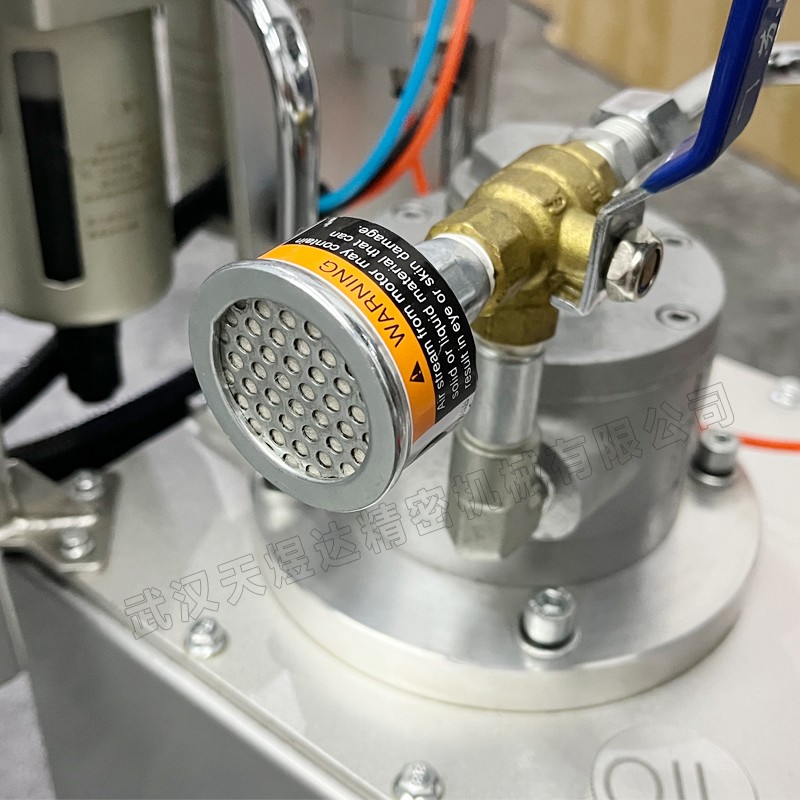

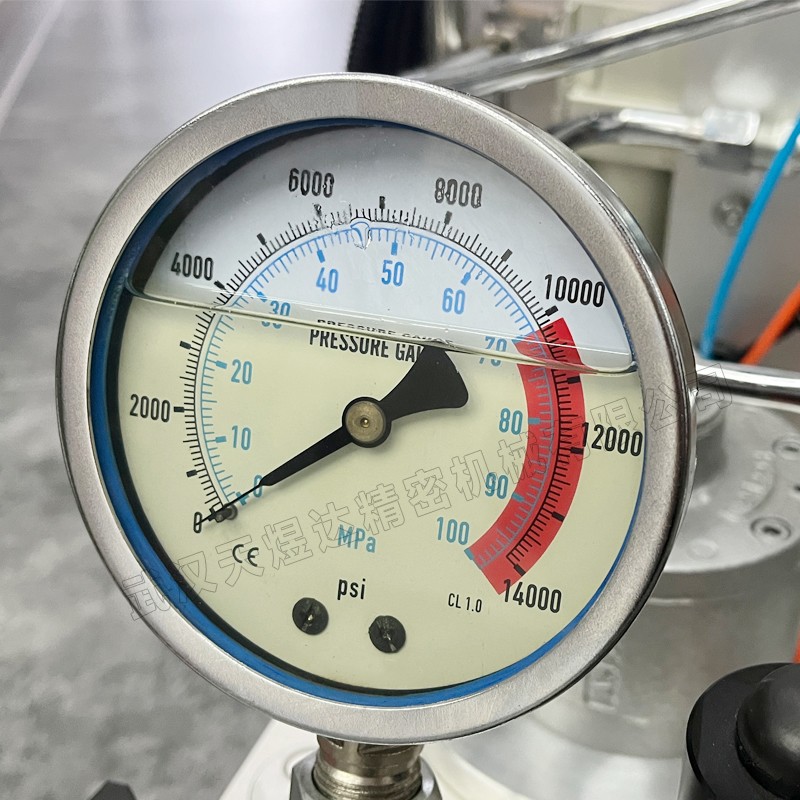

3. Pressure gauge: displays the working pressure of the hydraulic pump, with a range of 100 Mpa.

4. Oil pump protection frame: installed on the oil storage tank, used to carry and protect the hydraulic pump station.

5. Cooler: Implement forced cooling to reduce the oil temperature during the operation of the oil pump, thereby extending the working time and service life of the wrench.

6. Pneumatic control valve: realizes functions such as high-pressure hydraulic oil output, return oil control, and pressure output return oil switching; Implement the maximum pressure setting to protect the system from working normally under the set pressure.

Output port oil port size: NPT1/4 ";

7. Pressure gauge: measuring range of 70 Mpa (10000 psi), which is the highest working pressure of the oil pump;

8. Oil pump protection frame: installed on the oil tank to carry and protect the pneumatic pump station.

9. Quick connector: realizing hydraulic oil output/return function, quickly connecting oil pipes; Built in one-way valve;

10. Pressure regulating valve (overflow valve): limit the maximum working pressure of the pump station or adjust it to the required working pressure and lock it (it is prohibited to adjust this valve arbitrarily)

11. Liquid level gauge: observe the amount of hydraulic oil to ensure optimal oil usage; When the hydraulic oil is below 1/3 of the oil mark, it is necessary to add pump station specific hydraulic oil, otherwise it may damage the pump station

13. Oil discharge hole: plug G1/4 "to discharge hydraulic oil from the oil storage tank (used when replacing hydraulic oil);

14. Hexagonal screw: Sealed connection to fuel tank;

15. Fuel tank cap: Seal the fuel tank,

16. Ventilation oil injection hole: to discharge hydraulic oil from the oil storage tank (used when replacing hydraulic oil); The oil cap is designed with a ventilation hole function. When filling oil, unscrew the oil cap and install a filter inside to ensure that no impurities enter

Fuel tank; After tightening the oil cap, ensure that the air in the system is smoothly discharged.

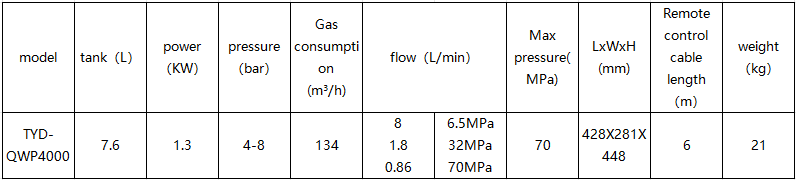

Product specification parameters