Wuhan Tianyuda Precision Machinery Co., Ltd.

Contact Detail

Adress:Building 15, Block E, Optics Valley Core Center, 52 Liufang Avenue, Jiangxia District, Wuhan City, Hubei Province

Tel:+86 153 8710 0967

E-mail:joy.hu@whtyd.com

Tel:+86 135 5467 0376

E-mail:Linda.Jiang@whtyd.com

Product Description

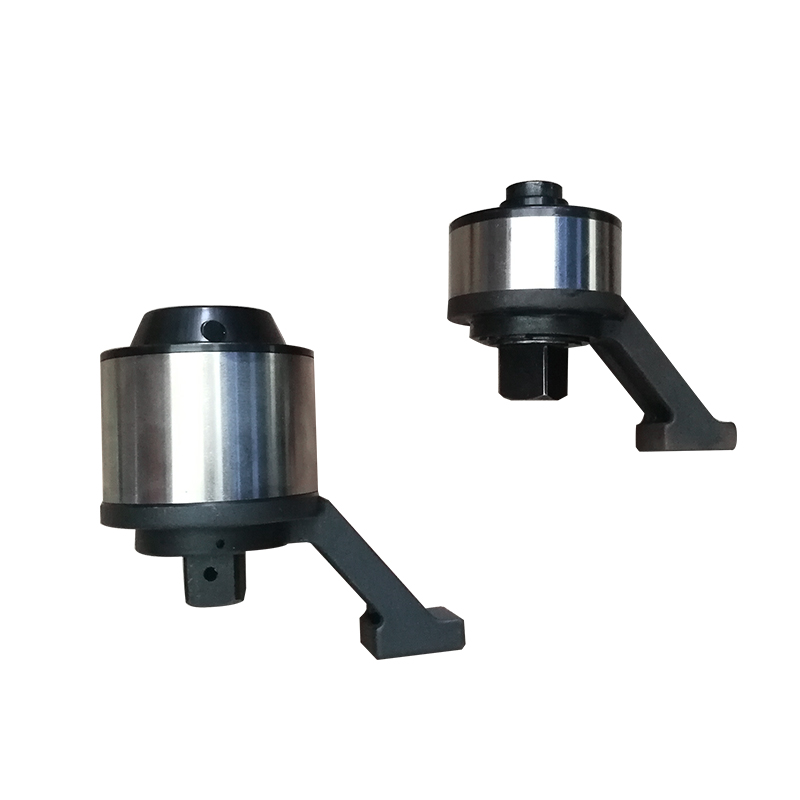

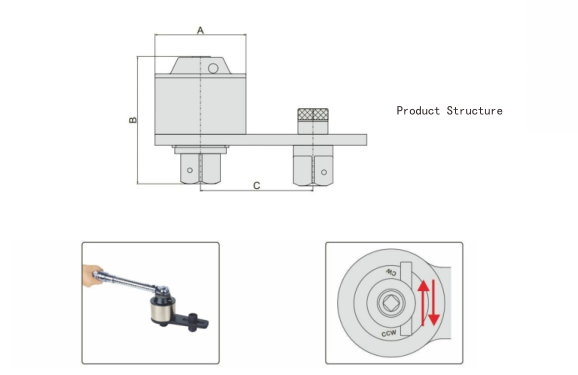

MDNF series torque multiplier is a manual torque multiplier,It is divided into flat type and bevel type, both of them can enable the operator to use a small input torque to achieve the effect of a large output torque

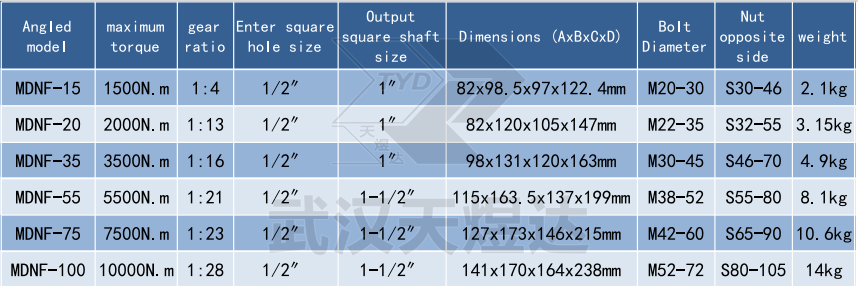

Technical Parameter

Product Features

● Suitable for occasions where space is limited and external power sources cannot be used

● High-efficiency planetary gear sets input small torque and output large torque

● The torque multiplier output torque accuracy is plus or minus 5%

● Made of special steel, long service life

● The reaction arm of the plate multiplier can adjust the position of the force cylinder according to the working conditions

● Special special reaction arm can be selected according to user requirements

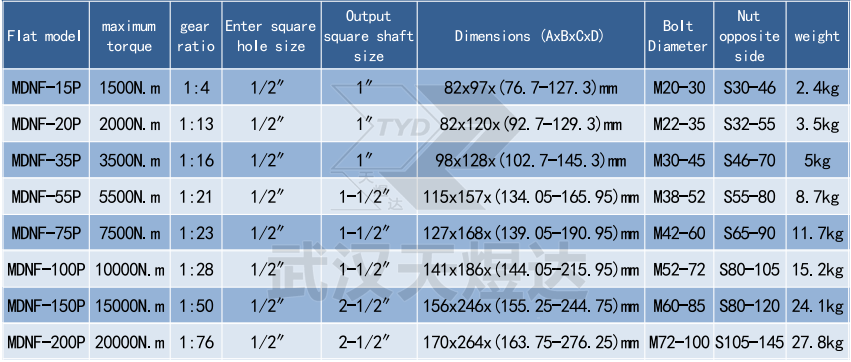

Operation

1. The following equipment is required to operate the torque multiplier:

(1) Powerplant or advanced impact socket

(2) Reaction arm

(3) Manual torque wrench

2. Operation precautions

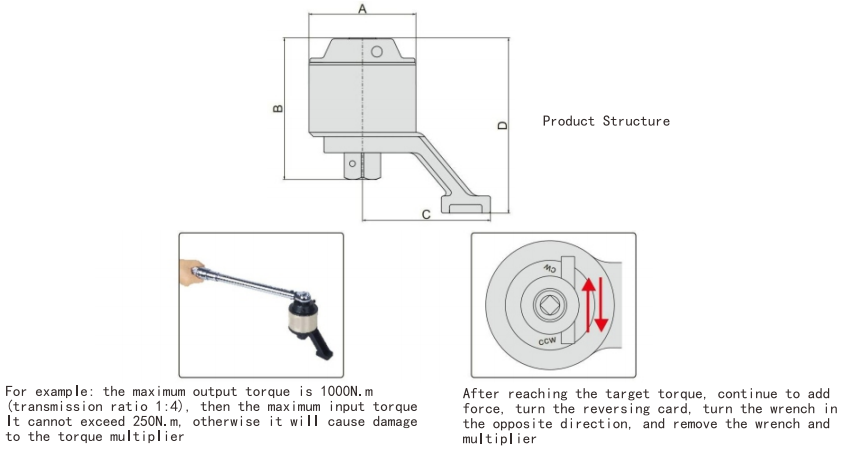

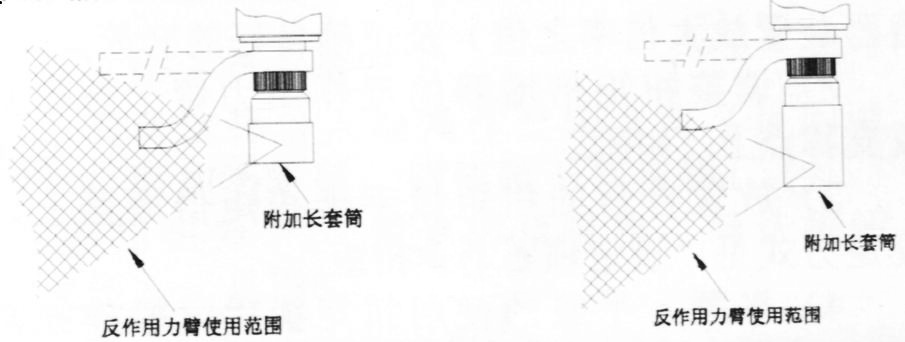

(1) When the torque wrench is manually operated, the reaction arm is rotated and placed in the opposite direction of the output operation, and a solid right-angle flat surface is found to lock the bolt, as shown in the figure, when the standard reaction arm is not suitable for the existing In the working environment, please make special orders according to the actual working conditions.

(2) When operating, do not exceed the use range of the reaction arm. For special applications or extended sleeves, a standard arm must be used, which can be extended but cannot exceed the operating range. Violating the restrictions on the use of the reaction arm will cause wear and tear or damage the multiplier output device, as shown in the figure

Note: Long sleeves should not be used as much as possible, because there is a risk of serious danger at the output.

3. Set the torque of the locking bolt

(1) Confirm the torque value of the correct locking bolt;

(2) Place a torque wrench at the input end of the torque multiplier; adjust the torque value of the torque wrench according to the magnification of the torque multiplier.

(3) Select a torque wrench suitable for driving the square head and put it into the input end of the torque multiplier. The torque wrench should be regularly calibrated with high precision.

4. Set the torque for removing the bolts

(1) Confirm that the torque multiplier will not be overloaded, and can be used to remove each bolt with a torque wrench;

(2) Adjust the maximum torque value of the input terminal according to the maximum output amplifying gear ratio of the torque multiplier;

(3) Select a suitable torque wrench (driving square head) at the input end.

Note: Some torque wrenches will not beep or bend when turned counter-clockwise.

5. Operating torque multiplier

(1) When tightening the bolt, set the correct torque value (the value of the magnification of the torque multiplier placement) and the correct and good sleeve.

(2) Adjust the reaction force arm of the torque multiplier to a suitable support point, as shown in the figure above;

(3) Place a suitable torque wrench on the torque multiplier. For the setting method, see "Setting the Torque of the Locking Bolt";

(4) Use the torque wrench smoothly and evenly, and operate the torque wrench until the "alarm sound" is heard. At this time, the correctly set torque value is reached on the bolt.